|

|

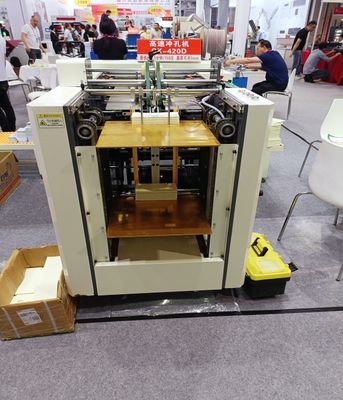

High Speed Full Automatic PP And PVC Cover Punching Machine Max Punching Thinckness 3mm One Minute 150 Times

|

|

Product Details:

Payment & Shipping Terms:

|

| Keywords: | High Speed Automatic Paper Punching Machine | Max Paper Size: | 420x4200mm |

|---|---|---|---|

| Min Paper Size: | 70x100mm | Max Paper Thickness: | 3mm |

| Max Working Speed: | 150 Times/minute | Machine Dimension: | 2.2m X 1.0m X1.3m |

| Power: | 380v /3PH/50Hz /2.3Kw | Weight: | 900kg |

| Highlight: | High Speed PVC Cover Punching Machine,Full Automatic PVC Cover Punching Machine |

||

CK-420D High SpeedAutomatic PP/PVC Cover Punching Machine Max Punching Thickness 3 mm one time

High Speed Full Automatic PP And PVC Cover Punching Machine Max Punching Thinckness 3mm One Minute 150 Times

Automatic High Speed PP/PVC Cover Punching machine is paper and board punching special equipment,mainly used for desk calendar,Hanger calendar,notebook,book,exercise book,thin grey board,PP board Binding,PVC board Binding .can not used for metal board

and wooden board. this machine adopts step drive paper,thickness can be adjusted

The Paper holding part adopts the wayof picking up and then inserting paper head,so that the paper surface should not be scratched to ensure the beauty and

quality of the product. after taking the paper ,it is sent to the punching mold through the coveyor belt,and then the paper is adjusted on three sides at the same time before punching.after punching ,the paper will automatically enter into the paper receiver according to the sequence of

paper size and margins can be adjusted. holes of various shapes can be punched by changing the mold

Model# CK-420D

| Max Paper Size |

420*420mm |

| Min Paper Size |

70*100mm |

| Max Paper Thickness |

3mm |

| Max Punching Speed | 150 times/minute |

| Power Requirement | 380v/3ph/50Hz/3kw |

| Weight | 900kg |

| Machine Size | 2200x1000x1300mm |

| Compressed Air Pressure | 3-6bar |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Our factory mainly produce two party of after printing products:

1:After-printing book equipment:double loop wire forming machine,double loop wire binding machine,semi-automatic punching machine, automatic punching machine,double loop wire binding &paper punching machine,Single loop forming spiral&binding machine,plastic spiral coil forming machine,plastic spiral coil binding machine,calendar hanger forming machine,book sewing machine,book folding machine.

Mylar Tab Lamination Machine

2:Binding material: plastic spiral coil,double loop wire,nylon coated wire,Metal Spiral Coil .PVC filament, PVC Binding Cover,Calendar Hanger ,Plastic Binding Comb

Our company advantages: we can supply after printing all kinds of full binding system:

1: first choose binding use double loop wire,our factory manufacture double loop wire forming machine and also manufacture double loop wire,after you bought double wire binding machine from us,if you also buy double loop wire from us. the double loop wire can smoothly bind by our double wire binding machine,they can work and cooperate very successfully.

2: second choose binding use metal single spiral coil,it is more easy we have one machine forming metal single spiral coil

and binding notebook at the same time.

3:third choose binding use plastic spiral coil,also very ok,we can manufacture plastic spiral coil forming machine and also plastic spiral coil binding machine.

Regards to our service:

After you bought machine from us,if machine has any problem we can help you to solve it.firstly after

you bought machine we will send a instruction book to tell you how to fix machine and operate the machine.if you have small problem with machine tell us,we take a vidoe to show you how to solve,if big problem you can not deal with it,we will send master to your company help you to solve

Warmly Welcome you call us and whatsapp/wechat @008613712492952

Contact Person: Robert Luo

Tel: 008613712492952

-

Easy Maintenance Automatic Punching Machine Safety Protection Easily Adjustable

-

High Speed Full Automatic Punching Machine Max Paper Size 120x104mm APM-420

-

Industrial Hole Punch Machine Paper Thickness 2mm For Notebook Hardcover

-

Paper Hole Automatic Punching Machine Max Punching Paper Size 450x390mm

-

Automatic Paper Punching Machine , Heavy Duty Punching Machine 1250kg

-

80-120 Times / Minute Automatic Punching Machine Binding Wire Comb Coil